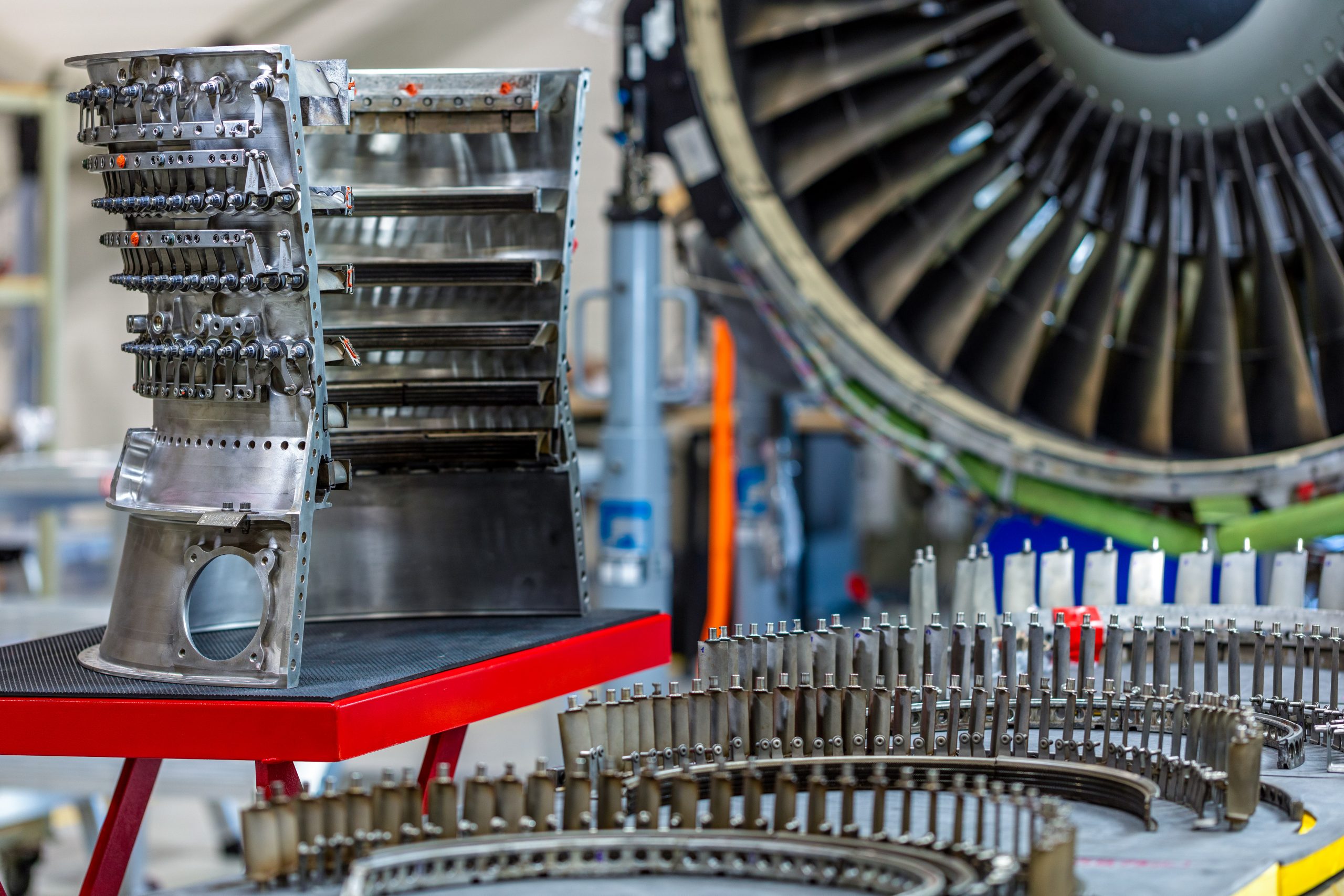

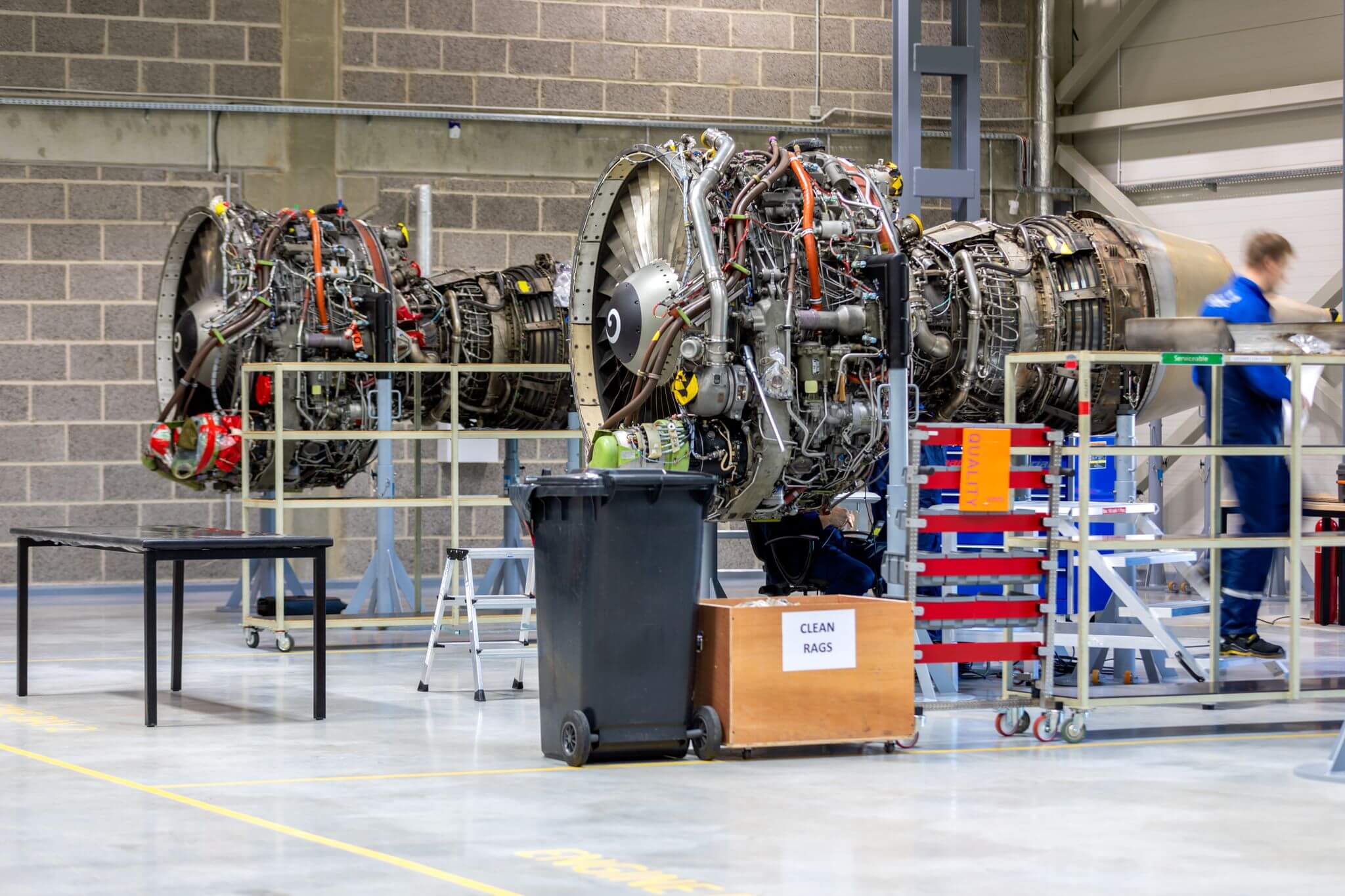

Forefront module of a jet engine is the area, most commonly damaged by external elements, so proper replacement is required to ensure consistent airflow to the compressor. Replacement and installation of specific fan components make maintenance processes more cost and time-efficient compared to complete module refurbishment.

Services

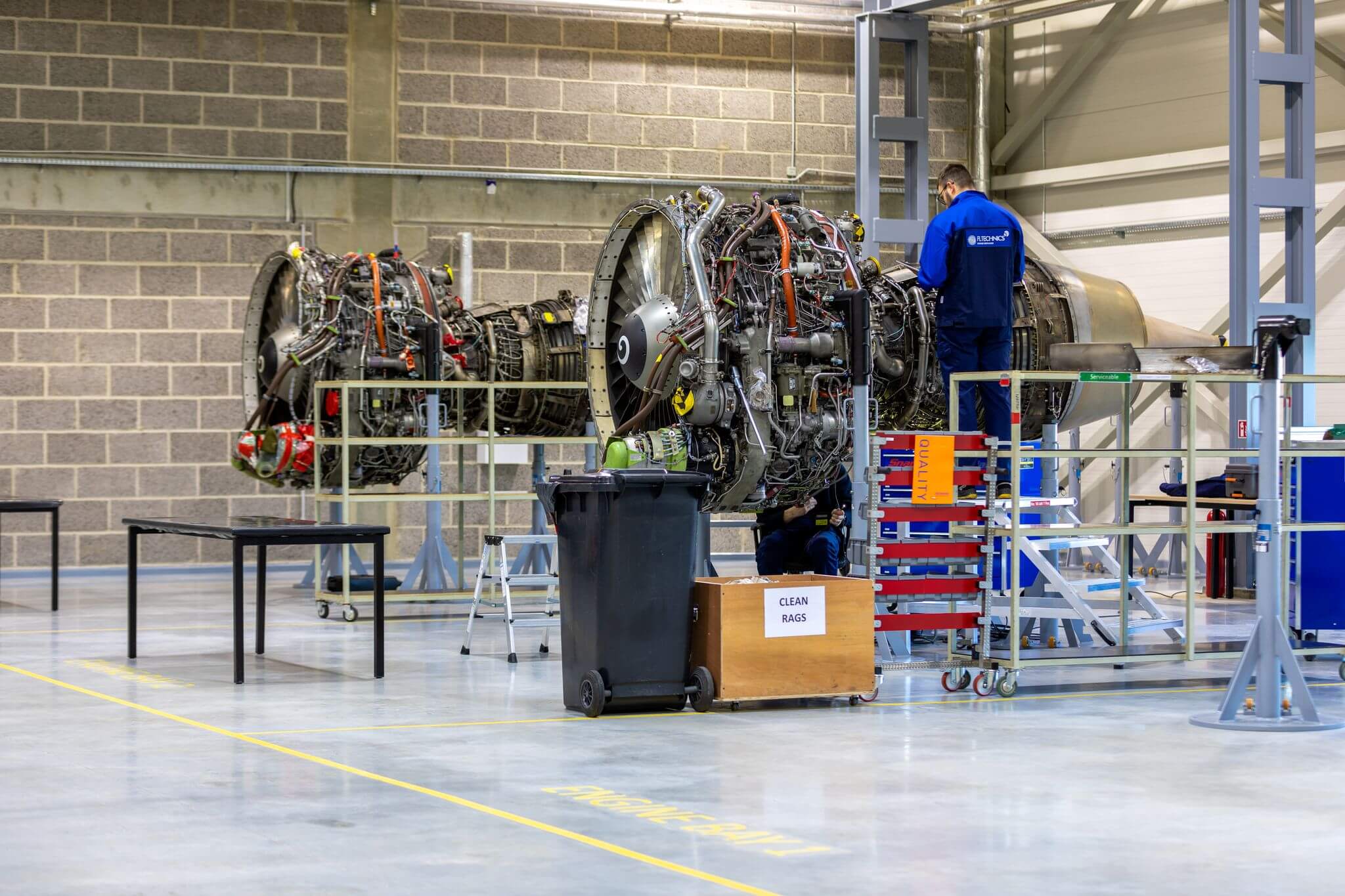

Quick-Turn-Activities Shop with On-Wing Support

Fan disk replacement

Fan and booster spool module (module - 21x) replacement

Quality servicing of fan and booster spool module grants most efficient airflow to the compressor and the turbine, ensuring efficient fuel consumption.

Fan Containment Case replacement

Containment case is a crucial element in aircraft engine structure for precise positioning and geometry of the fan, so proper servicing and replacement are essential.

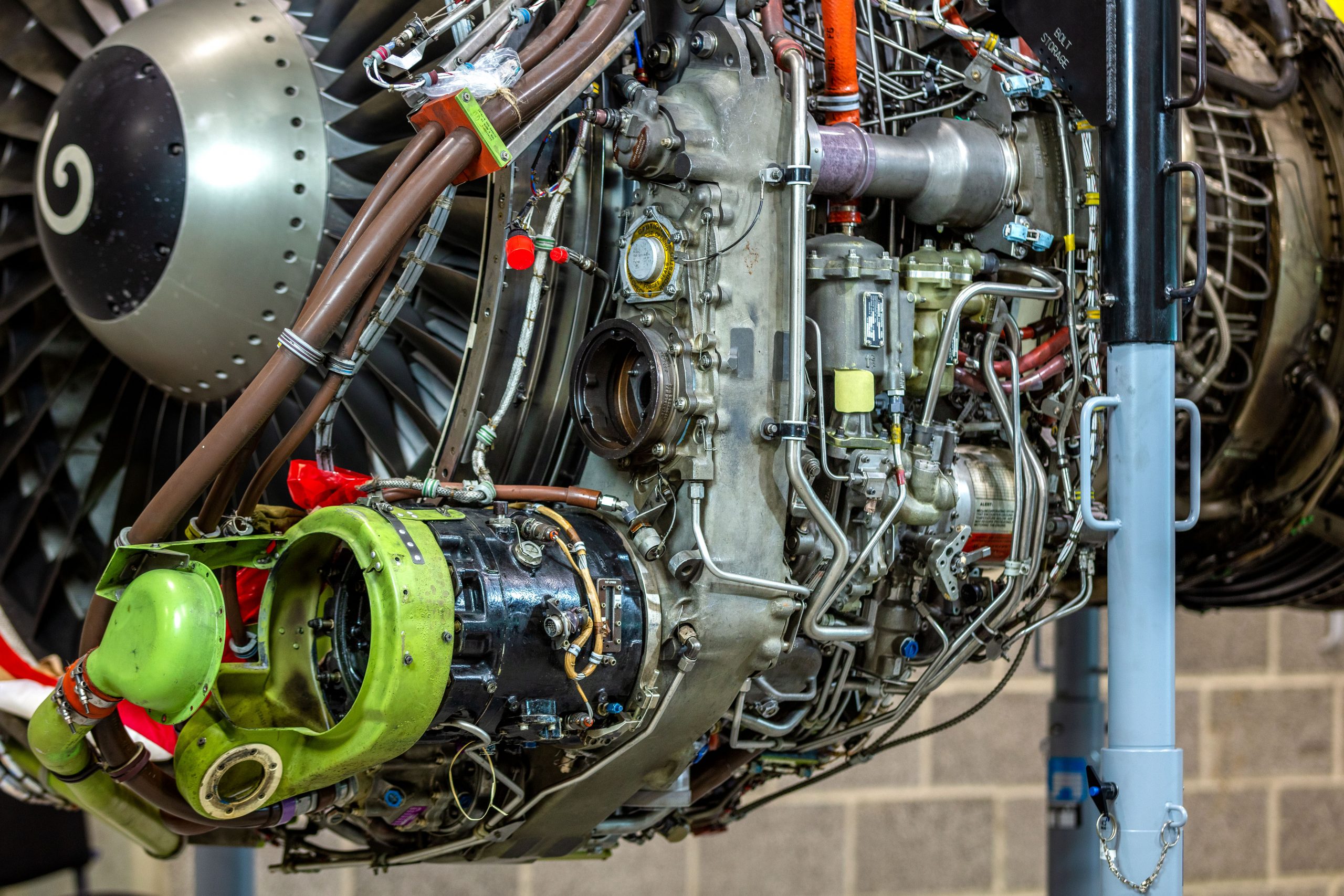

Bearing N1&2 support module R/I

Bearing support modules are key elements in aircraft engine structure for precise positioning and geometry of the fan. The replacement and installation services for bearing support modules require extensive experience and precision.

Boreblending

Service that allows to remove less significant HPC damage from outside an engine using state-of-the-art equipment. It’s a highly cost and time-effective way to carry out maintenance without taking the engine off wing.

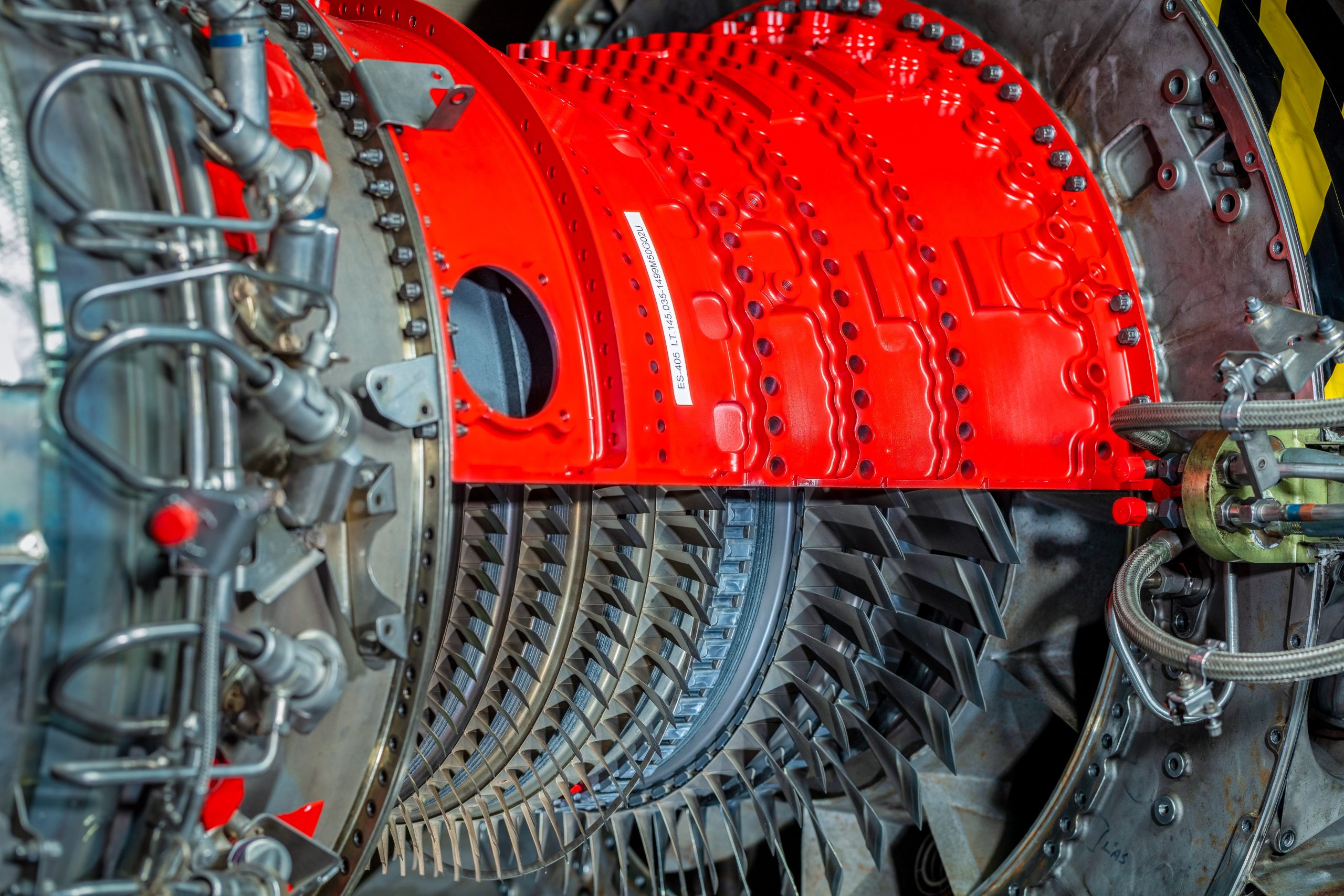

Top case repair (HPC blades replacement)

Removing an engine off-wing to carry out the repairs at an engine facility instead of sending the equipment back to the original manufacturer. Top case procedures allow for much more cost-effective maintenance.

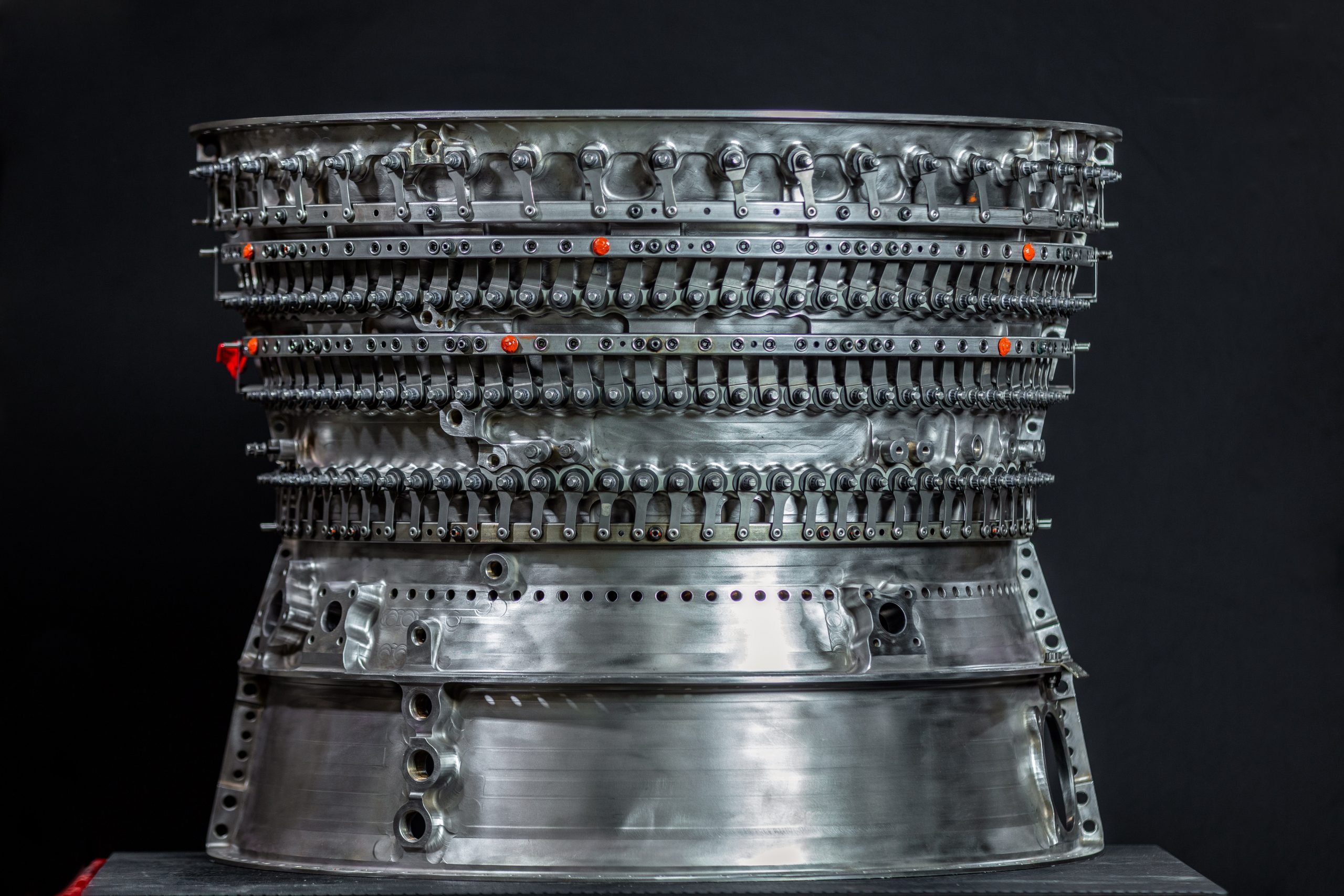

HPC shrouds and vanes replacement

HPC shrouds and vanes are components that have to withstand rigorous demands of turbine engines. Fast and professional service and replacement of such parts is required for safe operations of an aircraft.

Bottom case replacement and installation

HPC bottom case removal and replacement. The service requires removing an engine off-wing to carry out the repairs at our modern engine service facility.

VSV bushings Quick-turn

Quick and professional inner and outer VSV (Variable-stator-vane) bush replacement and other services.

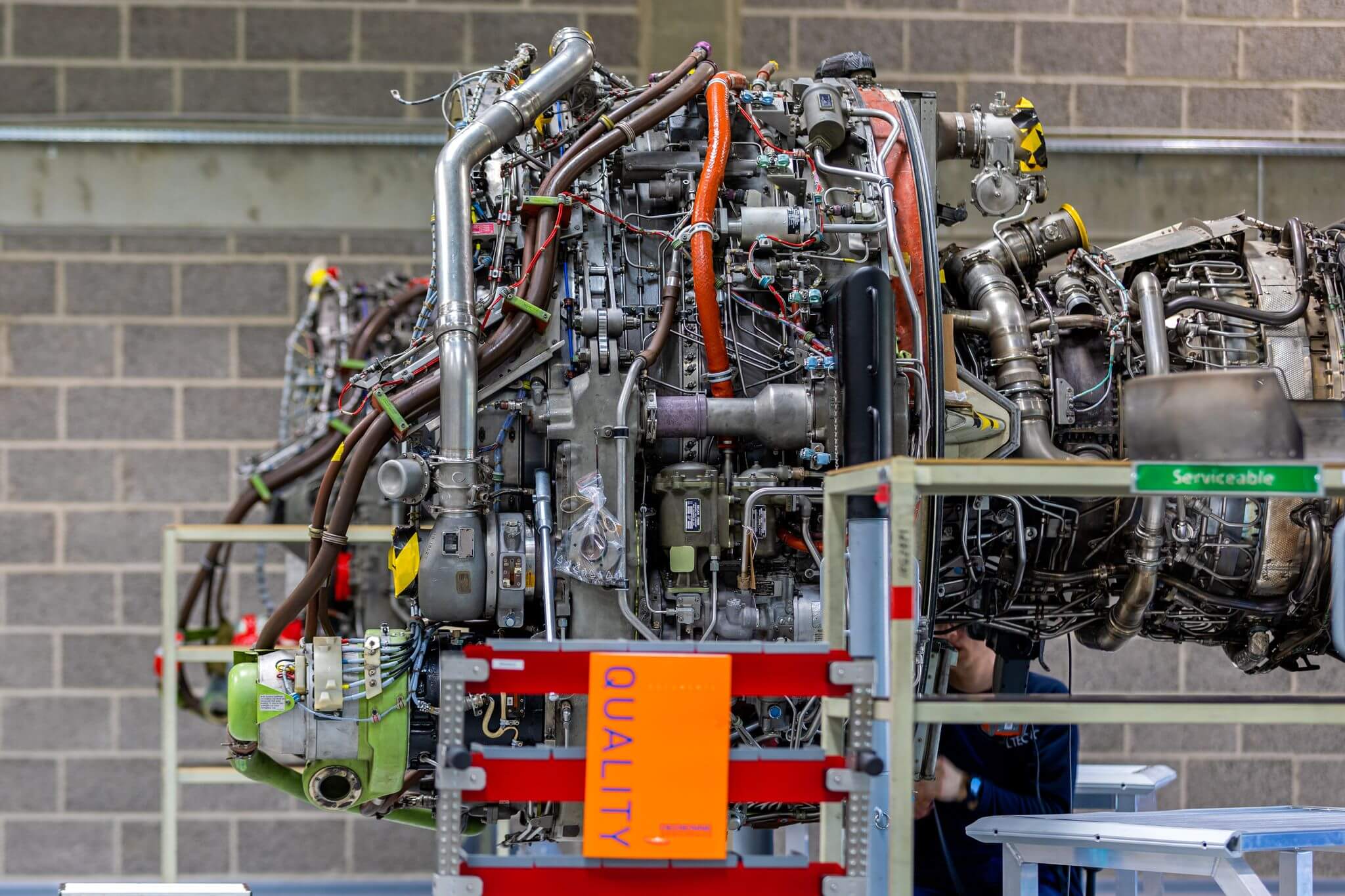

Combustion chamber replacement

Continuous exposure to extreme temperatures and high pressure requires constant attention and rather frequent replacement combustion chambers. FL Technics Engine Services’ professional team is equipped to perform maintenance on engine components at company’s modern hangar.

HPT NGV (module - 51x) Removal and installation and HPT nozzles replacement

Aircraft engine turbines endure constant pressure as well as high fidelity rotation that makes the module wear more often compared to other segments within the engine structure. Timely and professional maintenance of aircraft engine high-pressure turbine grants efficient fuel consumption, optimal thrust and, most important, safety.

HPT NGV replacement

To ensure safe and cost-efficient exploitation, high-pressure turbine’s nozzle guide vanes require monitoring and, if needed, replacement. Our team focuses on providing high-quality services in a time-efficient way.

HPT Rotor Module (module - 52x) R/I and HPT blades replacement

HPT Rotor Module require replacement in cases of extreme wear out or damage. Timely maintenance of aircraft engine high-pressure turbine modules grants fuel consumption efficiency, optimal thrust and safety.

HPT blades replacement

As one of key components of the rotor assembly, blades require close monitoring and urgent replacement if damaged or too worn. Our modern hangar is fitted with top quality equipment, required to carry out efficient maintenance services.

LPT NGV stg. 1 module (module- 53x) R/I and nozzles replacement

Because of constant pressure and high fidelity rotation that aircraft engine turbines endure while in operation, modules wear more often compared to other segments within the engine structure. Low-pressure turbine maintenance ensures safety and cost-efficiency of engine operations.

LPT NGV stg.1 replacement

To ensure safe and economical operations, low-pressure turbine’s nozzle guide vanes require monitoring and, if needed, replacement. Our team has years of experience in engine turbine maintenance and can provide high-quality services in a timely manner.

LPT MM (module - 03x) R/I

Experienced maintenance team provides quality LPT middle marker [VV1] removal and installation services our modern engine shop facilities.

Bearing N4 replacement

Extreme wear or damage requires bearings to be replaced to ensure safety of engine operations.

TRF removal in vertical position

Turbine rear frame removal requires exceptional care and precision as to keep all components in their top shape. Years of experience and industry know-how allow our team to confidently tackle the task and remove TRF in vertical position.

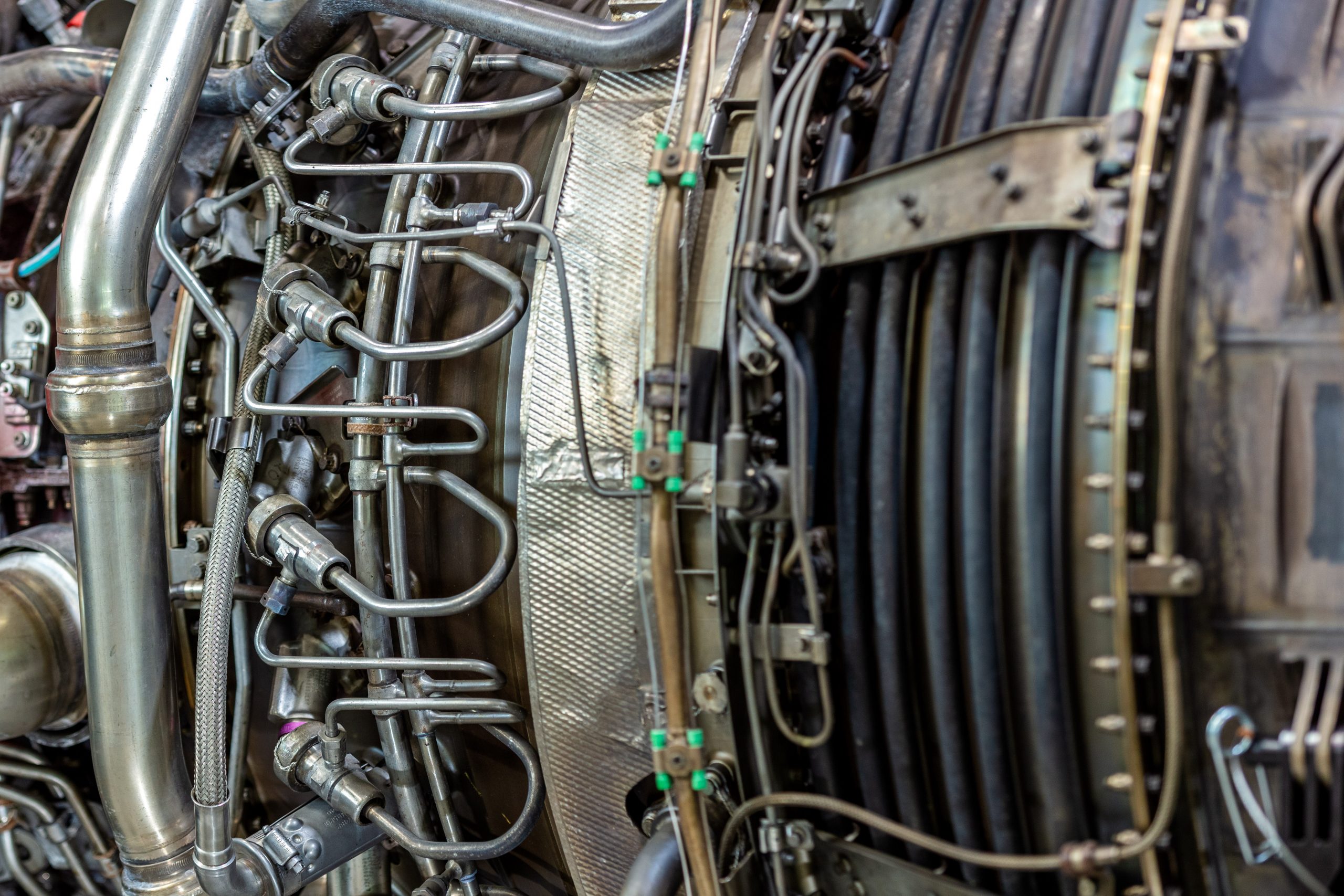

AGB, TGB replacement

Gearbox maintenance or replacement can significantly increase lifetime of an aircraft engine and improve overall performance through flight cycles. Our team of experts are certified and experienced in maintenance of Transfer Gear Box (TGB) and Auxiliary Gear Box (AGB), and can provide crucial services using high end tooling and modern facilities next to a major MRO hangar in KUN.

Engine BSI/External examination

FL Technics Engine Services offer thorough borescope inspections – an important engine’s function test’s part that’s conducted using full video borescopes. All borescope examinations are carried out by an experience team using modern and reliable technology.

Meticulous external engine inspections are just as important and can safe client’s costs and time as any minor issues can be eliminated before them becoming major ones.

Engine Preservation

When an aircraft engine is facing a long down time, certain measures have to be taken to reduce future engine maintenance costs related to inactivity. Since Jet engines are highly susceptible to the elements and can become faulty if not in use, engine preservation becomes a secure and economical choice.

FL Technics Engine Services provide on-demand engine preservation services and ensure engine protection against heat, direct sunlight, corrosion, and formation of residues, etc., maintaining parts in optimal condition.

Storage services

To prevent damage to jet engine components and extend their lifecycles, engines have to be stored in appropriate conditions. FL Technics Engine Services offer their modern facilities for engine storage.

One of the biggest threats to aircraft in storage is corrosion on the engines that, if not operated long enough, corrode due to water condensation that often comes from storage. Entrust your valuable aircraft assets to professional FL Technics Engine Services team’s hands and be sure of optimal engine storing and care.

QEC/LRU removal/installation

FL Technics Engine Services carry out high quality QEC and LRU removal and installation services. Company’s team operates from a modern facility in Kaunas, located next to major MRO centre – FL Technics base maintenance hangar in Kaunas FEZ.

We focus on efficient QEC and LRU maintenance services and provide quality solutions by following highest industry standards.